AI-optimized MiC Logistics

System

Modular Integrated Construction (MiC) is an innovative construction method that involves manufacturing building modules in a controlled factory environment and then transporting and assembling them onsite. This method has gained significant attention in recent years due to its potential to reduce construction time, increase on-site productivity and save costs.

Challenges and Problems

Complexity

Logistic planning is a highly intricate process, encompassing a multitude of interrelated factors:

1) resource allocation

2) meticulous scheduling

3) module demands

4) capacity of trucks

5) ever - changing traffic conditions

Difference

The characteristics of MiC make it different from traditional logistics transportation, involving:

1) both water and land transport,

2) storage or just-in-time (JIT) mode,

3) different traffic rules in Mainland and HK, and

4) border control regulations.

Time-consuming

Human-based logistics planning is time-consuming and cannot guarantee the performance. The performances, such as cost, risk, and impact on the site, cannot be visualized and perceived by planners ahead of the decision making.

Introducing of automated planning tool

Visualize the main KPIs of the designed logistics decision-making

Automated planning tool

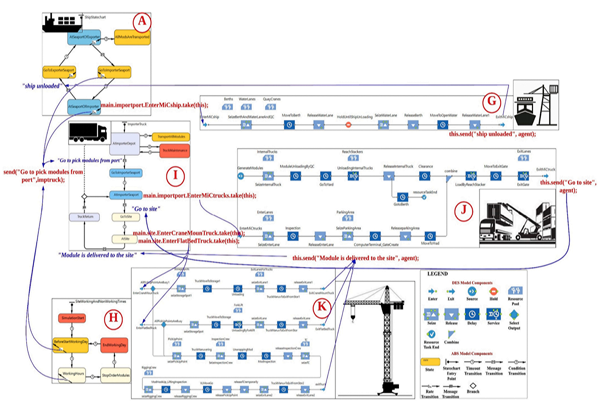

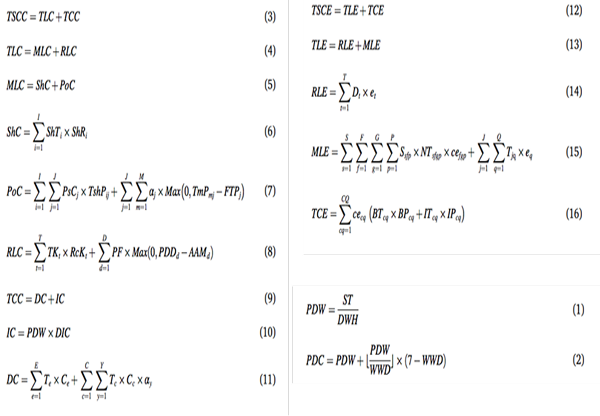

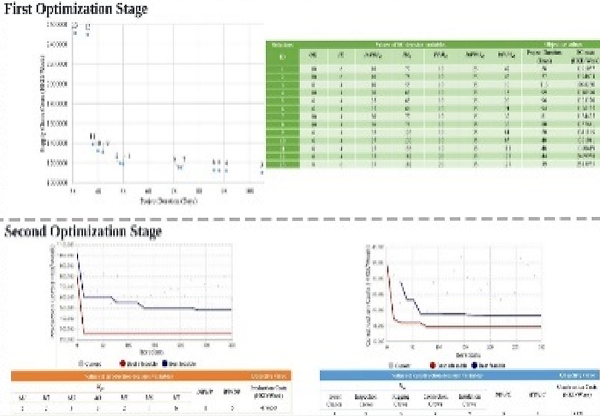

ICC developed an automated planning tool to generate the optimum MiC logistics plan considering both water and road transportation modes and numerous factors such as schedule, traffic, demands.

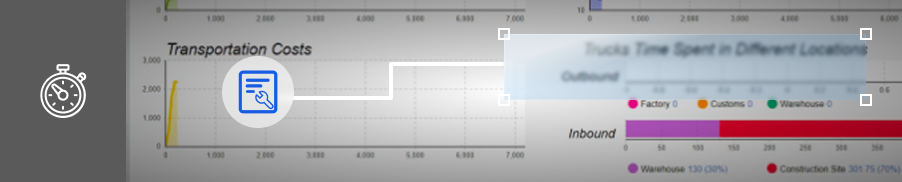

The main KPIs visualization

A platform is also developed to further visualize the main KPIs of the designed logistics decision-making.

Techs and advantages

Benefits

Comprehensive modelling

Our technology modeled 60+ logistics factors regarding storage, truck, etc.

Real-time planning

Our AI-empowered modelling algorithm generates the optimum logistics solution in a real-time mode.

Visualization of multiple benefits

This tool provides triple dimension benefits include time, cost, and sustainability.

Robust risk management mechanism

Our technology owns strong and powerful capacity to simulate and predict various logistics risks.

Case 1: InnoCell

- 17 floor tower, 418 hybrid modules, and 5 types of modules.

- Multimodal Sea-Land transportation.

- 2 TCs & 3-day construction cycle per floor.

- Temporary storage area.

Case2: Student Residence for HKU

- Two 17-floor towers, 884 steel-framed modules, and 6 module types.

- Land transportation.

- 2 TCs & 4-day construction cycle per floor JIT delivery.

The system modeled 61 logistics factors and analyzed 26 KPIs in terms of time, cost, and sustainability. The optimized logistics plan reduces duration by 28.0%, costs by 30.8%, and carbon emissions by 17.3%.